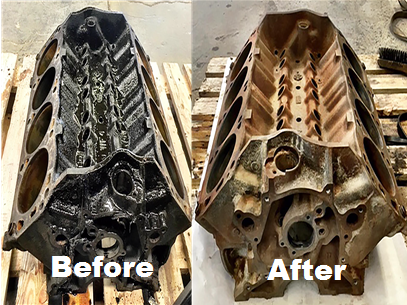

Cleaning of automotive parts is not only one of the most key procedures of a machine shop, but also one of the most important processes in engine repair. Prior to inspecting the engine parts to decide what needs to be done to them, they have to be cleaned in the first place. If the parts are not clean, then it becomes hard to measure and inspect them for defects. This post explains why it is it necessary to clean automotive parts.

Why is Automotive Parts Cleaning Important?

Regardless of what kind of engine work you do, cleaning the parts is almost always the first step in any job. Parts need to be cleaned before they are machined for four major reasons:

- It helps keep your shop equipment cleaner

- It uncovers the bare metal surface so you can see hairline cracks, and other flaws that may need repair

- It creates a clean surface that can be painted or left “as is” in the case of aluminum

- It helps remove accumulated dirt, grease, carbon, and corrosion from the parts

Cleaning is also one of the last steps you do after parts have been machined. It is necessary to remove the cutting lubricants, metal chips and/or grinding or honing debris from the parts. The final cleaning is particularly essential as anything that is not washed away can end up inside the engine. Residual shot blast media or metal chips that get stuck in a recess, or end up in an oil galley may find its way to the bearings.

How are Automotive Parts Cleaning Ovens Helpful?

Automotive parts cleaning has always been a complex process requiring special treatment and processing for components like engine blocks, brakes, and clutch parts. Specially, it is hard to keep parts, such as stators, rods, and crankshafts, free from rusting or coating. All these issues can be combated with the help of industrial cleaning burn off ovens. These ovens offer the following distinctive benefits:

- They are 100% pollution free.

- They reduce dependence on acids, chemical cleaners, solvents, and other such hazardous elements for cleaning purposes.

- They are environment friendly as they emit only odorless and harmless water vapors and carbon dioxide into the atmosphere.

- These equipment can clean multiple parts of an automotive system, such as brake components, engine blocks, clutch and cylinder heads, together at the same time.

- They come with the option of complete automation, which helps in saving labor costs.

- The ovens are completely safe and easy to operate.

- The fuel efficiency rate of such ovens is high.

- They are cost effective.

Irrespective of whether you want to remove years of accumulated dirt or just want to wash off new parts after machining them, every engine builder is required to periodically assess the cleaning processes conducted in his shop. This ensures that the processes are working well and there are no cleaning issues.